Zinc w clear hexavalent chromate 96 zinc w yellow trivalent chromate 336 zinc w yellow hexavalent chromate 240 zinc w black hexavalent chromate 300 zinc w olive drab hexavalent chromate 400 zinc w clear hexavalent chromate seal 240 chem processing inc.

Zinc clear trivalent chromate.

Clear blue yellow or black.

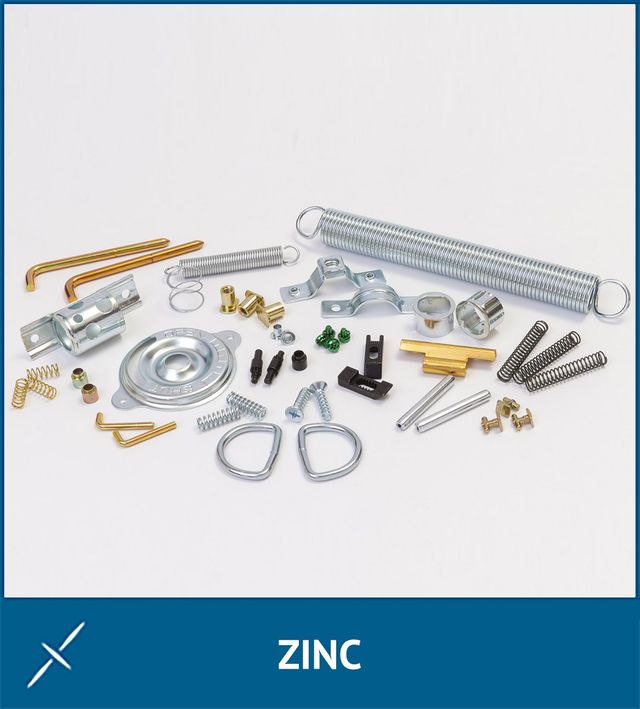

We offer many plating methods for various industries and offer the best available technology while reducing excessive.

P 1265 the coating serves as a corrosion inhibitor as a primer to improve the adherence of paints and adhesives as a decorative finish or to preserve electrical conductivity.

The process is named after the chromate found in the chromic acid used in the bath more commonly known as trivalent chromium.

For example if we do zinc plating on iron and if the coating is scratched somewhere.

Zinc trivalent chromate plating.

Tin zinc is available in a clear trivalent finish.

Chromate conversion coating or alodine coating is a type of conversion coating used to passivate steel aluminium zinc cadmium copper silver titanium magnesium and tin alloys.

Modern plating now offers a full range of trivalent chromate finishes chrome iii in clear yellow and black for zinc and in clear and black for zinc nickel zinc cobalt and zinc iron.

Offers precision rack and barrel zinc plating services to illinois.

The key difference between trivalent and hexavalent zinc plating is that the trivalent zinc plating process has a high efficiency with a uniform distribution than the hexavalent zinc plating process.

Zinc plating with clear chromate has yellowish discoloration.

Epi offers both hexavalent chromate and trivalent chromates in blue and yellow variations.

It can act as a sacrificing coat.

Chromates can come in many different color variations.

With trivalent blue bright chromates increases in the ph that lead to values greater than 2 3 1 8 to 2 0 being optimal for most processes.

The fix is a 0 5 nitric acid pre dip before the chromate use of a very blue trivalent chromate and close control of the chromate ph.

See reverse side for current specifications and availability.

Glmf specializes in trivalent passivation for zinc and yellow zinc and clear zinc and black zinc and olive drab zinc nickel stainless steel passivation and other finishing processes to meet our customer s specifications.

Components are zinc plated for corrosion resistance but the zinc plating itself is subject to early corrosion white rust.

Commonly used on zinc plated parts in order to provide protection from corrosion such as white rust or red rust.